Thread #2950082 | Image & Video Expansion | Click to Play

File: BF53F439-90B3-48C8-A689-6805519E54A3.jpg (151.1 KB)

151.1 KB JPG

Thinking about building a small cnc mill for small steel and aluminum parts. I’d like to make the thing mainly out of aluminum extrusions.

I was thinking that a fixed gantry design like picrel would be the most rigid, except I’d like to mirror it so there are diagonal braces on both sides and to increase the depth of my work area.

Is this the most rigidity possible given the size and format constraints?

106 RepliesView Thread

>>

>>

File: prototrak.jpg (172.4 KB)

172.4 KB JPG

>>2950082

dont most edamamebois that build 80/20 routers get disgusted with the lack of rigidity pretty quick and move on to something else? and theyre just trying to cut interwoven cellulose

>>

>>

>>2950082

this thing might cut plastic, maybe some soft wood.

you will spend more on end mills trying to cut steel on that than just buying a grizzly g0704 or something and converting it to cnc

actually is that a taig headstock on that thing in your model?

just buy a taig or sherline imo.

one of those will be infinitely better than this

>>

>>

File: file.png (1.3 MB)

1.3 MB PNG

>>2950082

>Thinking about building a small cnc mill for small steel and aluminum parts. I’d like to make the thing mainly out of aluminum extrusions.

You'll need to replace that with plate aluminum parts for steel or aluminum. you can start off with aluminum extrusions to cut / drill aluminum plate.

or just buy a chink cnc machine and modify it with a chink 110V 1.5KW ER11 spindle.

>>

>>2950082

>steel

lol

Milling steel on a router like this is going to be unbelievably slow. Like you can get a tiny feature into a tiny part over 20 minutes, while holding the spindle by hand the entire time to reduce vibrations and add preload. And it's still going to break at least one endmill per operation.

Aluminium is much more forgiving but still painful. If you do not particularly NEED large parts, it's a very good idea to build the CNC around a machine vise, since it immediately resolves all your workholding woes. And then you should adjust the Z axis so it's the smallest reasonable distance away from the vise. Make sure to use beefy linear rails. The open bottom SBR12/SBR16-UU round slides have tension adjustment, the MGN types don't, but larger MGN rails are very solid.

>>

>>2950082

Your design looks like it is 8 times as stiff as my cheap wood-aluminium thing, but the table looks like it’s exactly the same as mine so that would be a weak point unless those two rails are some super tight tolerance hard steel kind of slides I don’t know about. And don’t you need some plates on the diagonal braces as well

>>

>>

File: maxresdefault (1).jpg (136 KB)

136 KB JPG

i've seen some mexicans make diy sliding tables out of slabs bolted together. do you guys think this would be rigid enough for machining on it?

>>

File: 170657-2048x1136.jpg (230.8 KB)

230.8 KB JPG

if i bought two of these alibaba sliding tables and bolted them on an L shaped steel frame, wouldn't I technically have a milling machine? the top slide would have a router with a spindle under it. the spindle strapped in place by two bolted flange bearings. the bearings bolted on plates secured to the vertical sliding table. voila

>>

>>

File: 170657-2048x1136.jpg (435.3 KB)

435.3 KB JPG

>>2950584

like so

>>

File: file.png (682.9 KB)

682.9 KB PNG

>>2950592

do they have ball screws or do they have threaded rod?

if they have threaded rod, they are junk and not worth your time.

What you should do is source 3 linear stages with rails and ball screws and build your own.

>>

File: braces.jpg (94.2 KB)

94.2 KB JPG

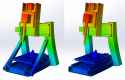

>>2950082

Diagonal braces do surprisingly little. First of all, the base isn't perfectly rigid and, unless ridiculously overbuilt, twists under its own load by about the same amount. Second, by the time the gantry legs are beefy enough to not twist into a pretzel (a major weak point in many designs), they're also beefy enough to transfer the forces into the base without much need for additional bracing. For pic related the difference is less than 7% which is not worth the trouble imo.

>>

>>2950082

I was watching a weird chinese guy build a 4 axis like this in his 1 bedroom apartment, he had to keep it small so it would fit in soundproof cupboard (lol)

Realistically i think the Not An Engineer / Kris Temmerman design is the only one that would work but what would i know, fucking nothing

>>

>>

anybody in the 1st world try out one of the chinkshit ddcs controllers? i see them on lots of ruskie builds but it seems like they have no look ahead so they slam on the brakes and creep around every g02/03 circular move. that seems like it would completely defeat any high speed roughing programming

>>

>>2950898

Need to make it out of steel if you want it to be good the stiffness of steel is around 2-3x stiffer than aluminum. Your best bet would to design it out of an epoxy granite base and 1/2" -1" thick plate weldments to hold the table and spindle assemblies. It needs to be super duper stiff if you want to be machining steel with any kind of efficiency, look at how much mass people add to their Bridgeport and things to adjust the vibrational frequent of the machine. Look at how much mass and stiffness there is on a modern consumer mill, and that is the weakest you should go

>>

File: 2ndops.jpg (457.1 KB)

457.1 KB JPG

>>2953374

>look at how much mass people add to their Bridgeport

wtf are you talking about? poast proof

ive been in and around west coast job shops for 40 years and never once seen mass added to a bp mill. with the exception of insurance mandated bolt downs otherwise all of them were simply plopped on the floor and plugged in without complaint. and anybody that claims a bp will chew away with a 3/4 endmill buried 2" deep in steel is full of shit. theyre not a #5 k&t

>>

>>2953374

>Need to make it out of steel

>Your best bet would to design it out of an epoxy granite

So which one is it? FYI elastic modulus of EG is about 15% of steel, and while it's a useful material, it's quite a bit more of a meme than a lot of people love to imagine.

>>

>>

>>

>>2950898

>Diagonal braces do surprisingly little.

Not trying to be a jerk anon, but if you put diagonal braces where there is the least of distortion then you shouldn't expect much. Can you run another sim with braces protruding away from the bed?

>>

>>

>>

>>

>>2950898

How did you set up your forces? It looks like you did it as a force in the +z direction, which for a drill press would be fine, but a mill will generally work more in the x and y then the z direction.

It also appears most of the deflection is due to the z axis/tool head. Suggesting adding rigidity to the tool head/mount would be a good place to start rather then braces.

>>

>>2955803

It may help a bit but you'll need at least a similarly big tube or a stack of tubes in the base to resist the resultant forces and all the accompanying jiggamajig because the bottom of the base is not flat anymore. Depending on design it might also hurt the torsion stiffness of the base or introduce more welding and distortion or make aligning and keeping everything flat and square more complicated. Might as well just simply use a bigger tube for legs/pillars, which is sort of what already happened on that pic, was hoping to use the same tube for everything but turns out those legs are a major weak point. After seeing the simulations I now always kek @ chink machines with legs cut out of plate. Can't even begin to imagine how much they flex with sideways forces.

>>2955954

>How did you set up your forces?

66% of total force on X axis, 56% on Y and 50% on Z. Yes it doesn't add up to 100% because it's a vector sum. Iirc got it from some sort of old standard on (manual) milling machines due to lack of better reference.

>It also appears most of the deflection is due to the z axis/tool head.

Yes X and especially Z carriages usually make a big part of total deflection due to mass and geometry constraints. There's no good way around it, you can only choose what kind of compromise to eat.

>>

File: file.png (1.1 MB)

1.1 MB PNG

>>2955948

You want the 3030 prover max with ball screws and linear rails.

https://www.youtube.com/watch?v=f2c4BXAzRu4

3030prover max + something like a MAFELL Milling motor FM 1000 PV-ER or Sorotec SFM 1000 PV-ER spindle is literally the best thing you can buy for the price.

OR go the super cheap route with 3030 prover max and chinese VFD/110V 1.5KW ER11 spindle.

>>

File: Screenshot_20251109_220946.png (114.5 KB)

114.5 KB PNG

this you?

>>

>>

>>2950152

>You'll need to replace that with plate aluminum

While i am not a fan of aluminium profiles for cnc mills, these plates would be less stiff and more expensive and thus a terrible choice.

The design of that entire machine is just bad and was done by someone clueless on stiffness, design for manufacture and economics.

>>2956337

>MAFELL Milling motor FM 1000 PV-ER or Sorotec SFM 1000 PV-ER spindle

These are terrible compared to chink ER spindles for 1/2 to 2/3rd the price since those have actual vector VFD torque regulation and are brushless instead of these garbage brushed universal motors with at best phase angle control.

Please stop giving terrible advice.

>>

>>

>>

>>

>>2956321

>but you'll need at least a similarly big tube or a stack of tubes in the base

I'm pretty sure you can minimize deformation with 4 extra square tubes per side. That being said, the original deformation seems pretty easy to model and predict so prevention or minimization is more expensive than a few extra lines of code.

Also, the diagonal beams seem to be there to minimize the gantry's bottom screws' radial effort over the axial effort, as they have less strength on those axes

>>

File: cnc2.jpg (183.5 KB)

183.5 KB JPG

>>2958120

There are countless ways to "minimize deformation with 4 extra square tubes per side" so just please draw a sketch next time.

In any case here's what the above machine ended up looking like. There are some things that still need polishing but the frame is more or less final. It's about as rigid in the sim as a similarly sized manual mill designed to make massive cuts with big mills should be, and trying to beef it further gives diminishing results, so I'm stopping at that.

>>

>>

>>

>>

>>

>>

>>

File: Capture.jpg (115.9 KB)

115.9 KB JPG

>>2959515

A nigger with a sherline which is about the same size but can actually cut and uses full size end mills.

This is what the column on that toy looks like.

>>

File: Capture.jpg (213.6 KB)

213.6 KB JPG

>>2959526

This is the 'table'.

>>

File: Capture.jpg (238 KB)

238 KB JPG

>>2959527

This is the motor.

It's a stretch to call this thing a mill.

>>

File: meat go.jpg (55.9 KB)

55.9 KB JPG

>>2959439

>It's about as rigid in the sim as a similarly sized manual mill designed to make massive cuts with big mills

>i dont have a clue but muh computer program shit out some garbage ill preach as gospel

why are green jr engrs so fucking arrogantly retarded?

>>

>>

>>

>>

>>2959439

I thought about providing a sketch but I'll let you have as food for thought why that might be a bad idea if no one has shared here an arragement I can point you to.

That being said, do you have access to topology-optimizing software? That would also be useful to figure out where and how to add reinforcements.

>>

>>2960891

>do you have access to topology-optimizing software? That would also be useful to figure out where and how to add reinforcements.

I could probably find something to use but I won't bother for a few reasons:

- I don't have the manufacturing capabilities to build anything that isn't primitive enough to just optimize manually by trial and error. It'd probably take more work to beat the program into submission so it won't propose me shit I can't make.

- for that kind of optimization to be even worth the effort you need to have a very good idea about expected loads and type of work the machine is being designed for, and the ones derived from a simple testing procedure from and old standard for a different type of machine do not anywhere nearly cut it. Without that it's garbage in - garbage out.

- I'm already halfway into making actual hardware and I'm not throwing it away just because there's something 5% better.

>>

>>

>>

>>

>>2961808

Naw it makes perfect sense

The forces involved (the X component specifically) are twisting the frame around the axis pretty much parallel to the braces so they don't do shit. They do help resisting the Y and Z forces but the frame is strong enough in that direction already and the majority of deflection happens elsewhere, so again they don't do much.

>>

>>

>>

File: werewaiting.jpg (61.2 KB)

61.2 KB JPG

beer can cnc status check?

>>

File: itonlymillz.jpg (147.1 KB)

147.1 KB JPG

>>2950082

>spend thousands building a shitty aluminum frame toy

>spend hundreds and get a box way pallet change jap mill built to hold tenths

the choice is yours

>>

>>

>>2968288

>Gee I wonder why

mostly because anybody that needs an hmc is into big money production. and the $5k rigger rape loadout fee scares everybody else

these machines were running parts in oct. the auction was a combo of old owner/lost big contract/50% rent increase

there was also a matched triple set of 400mm mori hmcs that brought $5k/ea. thats a lot of floor real estate needed at 12x30ft each

>>

>>2968334

>>2968288

>>2968098

>Do contract IT work for a metal working company

>Owner is a tight ass, buys used machines

>Gets a 'new' CNC machine, calls me in to find out why it 'isn't connecting to the network'

>The draftsmen all use SolidWorks and dump the files on a network share

>The monkeys operating the machine browse to the share, download the file, and push the button

>The fucking thing runs an embedded version of Windows based on 98 SE

>It doesn't support any newer file transfer protocols so it can't 'see' the servers

>Owner wants me to enable older, insecure network protocols on the servers

>Politely but firmly tell it ain't fucking happening and explain why

>I tell him the monkeys will just have to put the files on a USB drive and walk them over to the machine

>He doesn't want the monkeys wasting their time

>I say I can install a machine right next to the CNC so they don't have to walk very far

>He doesn't want to pay for a new machine

>Hem and haw for a bit until he starts getting angry that I won't downgrade security

>I tell him to call his lawyer and loop him in on the conversation

>Lawyer says that if he does this, is hacked, and his insurance finds out, they won't cover him

>"Oh"

>I sell him a NUC and set it up right next to the CNC so the monkeys don't have to walk very far

>Still get a call at least once a month from a monkey because the machine is not connected to the network

>Tell them to look to their left and follow the instructions on the giant red and yellow card taped to the second monitor next to the CNC machine control panel

>15 minutes of time is billed to the contract for that month and I make $38.75 every time that happens

>>

>>2968334

>spend hundreds and get a box way pallet change jap mill built to hold tenths

>but $5k rigger rape loadout fee

>but thats a lot of floor real estate needed at 12x30ft each

Like pottery. And let's hope it's not one of those machines that has gps and all kinds of sensors and will lock out when you move it and you'll need to call a manufacturer's rep to inlock it - if they don't decide you're not allowed to have it that is. Will also likely need thousands in proprietary parts and maintenance on the regular that someone looking at shutty aluminum frame toy clearly cannot afford.

>>

File: 20260101_103550.jpg (750.3 KB)

750.3 KB JPG

>have a tiny mill with a spindle that only takes 3/8" tools

>tired of cutting stock by hand

>buy some slitting saws

>no one sells a 3/8" shank saw arbor

>spend week making arbor out of bits of welded together mild steel

>crazy bad runout because I dont know what I'm doing

>try it out, cuts surprisingly ok doing 15-20 thou passes

>cut a few parts with it

>getting tired of slow cutting, decide to try a full depth cut like people on youtube do

>saw sticks into stock, flexes the machine and bends arbor

>saw now chattering and rubbing sides of cut

>stick arbor in vise and smack it with a mallet opposite to the bend

>saw spins ok again but still some chatter, maybe if I run it really fast it will straighten out

>wow this is working

>2/3rds into cut and saw starting to stall on every pass

>can't even cut 5 thou now, wtf.jpg

>take saw out and check teeth

>teeth completely rounded on sides from high speed rubbing, saw is toast

>search how to sharpen, need $1200 machine of dubious quality from china

This hobby is fucking retarded, if you can't buy the real tools then don't bother, DIY solutions will just cause headaches.

>>

>>

>>

>>

>>2968406

Now imagine running a horizontal milling machine like the old days, your entire life consists of fucking around with giant oversize slitting saws and arbors. Low feeds and speeds.

>search how to sharpen

Just bin it and start again.

>>

>>

>>

>>

>>2968550

A real arbor (not chinese tool shaped object) would at least spin true. I recut the arbor while mounted in the spindle and got the runout to be lower, but it still goes all over the place once it starts spinning.

I have a rotary table, I don't have a grinding wheel that I can mount in the spindle that will spin true. Half the pain is my spindle is a miniature MT1 taper.

>>2968526

>Just bin it and start again.

I sharpened it by hand on a grinding wheel, it still rubs on the sides but at least it's cutting again.

>>

File: a672a9e4-f2da-4cee-b913-b31c00cab7a4-91094549.jpg (1.5 MB)

1.5 MB JPG

>>2968528

The cast iron one is the FF230 which actually looks like a decent machine, but costs more than 3x as much as the toy pictured here >>2959449 ,and for that kind of price you can get a bigger chinese mill and upgrade it to be good.

I wish I could find a decently priced accurate cast iron XY table like that though, would love to ditch the aluminum table on my sherline.

>>2968553

Then we're back to my original argument that it's a toy, a dremel probably has more power.

>>

>>2968562

>I have a rotary table, I don't have a grinding wheel that I can mount in the spindle that will spin true

You're not building a surface grinder, a bit of wobble won't hurt as long as there's no slop in the bearings. Btw it doesn't have to be the mill spindle itself, a dremel or even bench grinder will do as long as you can strap it square and rigid enough to your mill. In fact it doesn't have to be a mill at all, you only need something to give you a bit of motion that doesn't even have to be linear to swing your improvised grinding spindle in and out while indexing the saw, which is simple enough to diy. You don't need the actual rotary table while at that either as long as you use it to make some sort of a cog or indexing plate first to fix the saw at repeatable angles. You've got one tool, feel free to use it to make the ones you don't if you don't have the money to buy them. Doesn't matter if it's janky, if it makes the job faster or easier than doing it by hand then it's worth it. That's how you build competence in the first place.

>>

File: 5975b3349f1cb.jpg (203.8 KB)

203.8 KB JPG

>>2968566

Dremel doesn't have an XY table for one which makes it useless for certain jobs no matter how much power it has.

Pic related is a toy as well (compared to something like bridgeport), it only matters how you play with it.

>>

>>2950082

>mill

no

>router

yes

so here's the thing. using aluminum extrusions is theoretically fine, but you're asking a very dinky material in a very dinky form factor to cut a comparatively very stout material. mild steel by milling standards is pretty manageable, but you're basically asking a cnc router to do this. is it possible? yes, with a lot of qualifiers. what size material? are you trying to do a big facing pass, or just milling a profile? is it bolted down really well? how about tooling? are you going to try drilling with this nigger rigged cnjank? it's a lot of things to keep track of.

aluminum extrusions will get you to a place where you can mill and possibly even drill aluminum billet, which could then theoretically be used to make an actually good frame.

problem with above plan: fucking stupid amounts of money. you'll have done something really cool, but it's far from cost or time effective. my advice? save up for a desktop manual mill. you'd be surprised at how capable they are. remember: you don't actually *need* cnc, it just makes things a hell of a lot easier and removes a good chunk of human error. a manual mill with a skilled operator is, in many cases, actually more capable. it all kind of comes down to theory and setups.

TLDR: i really wouldn't, you're describing a router. save up the money you'd spend, wait a while longer, get a proper manual desktop mill.

>>

>>2968367

oh brother. i got a story for you. i'll tell it from monkey's point of view. i'm a proper machinist, i do setups and some programming, but this guy was a fucking button pusher larping as a machinist who ended up getting fired for not being able to show up *or* do his job *or* be sober doing it.

>be me, retard

>setting up job

>get new program on routing paperwork

>load it

>see old program in folder

>ok whatever

>delete folder, clear everything out for space

>go to find new program

>notthere.gcode

>oh shit

>look again

>all the folders are gone

>call a programmer out of the office to take a look

>he says "ok i'll just grab it from the office, it's fine, brb"

>he comes back half an hour later

>"anon, you deleted our server"

this fucking idiot wiped the ENTIRE MAZAK FOLDER from our servers. we have no read/write protections on the mazak mills: what happens at the machine is mirrored on the server. this guy wiped our entire server's worth of mazak programs from the machine. the only reason we still have anything is because it got backed up to a flash drive in the IT guy's office and we were able to roll it back a couple days. i think we ended up losing a good amount of programs anyway.

so, the only thing worse than being hacked is not implementing good permission structure. never trust a grunt with logistics

>>

>>2968589

>Dremel doesn't have an XY table

I've seen some things, desperate people resort to desperate measures.

>>2968589

>Pic related is a toy as well (compared to something like bridgeport)

It uses nearly full size cutters and can cut the same materials so not really. The proxxon by comparison would have trouble milling even aluminum accurately.

>>

>>2968608

>the only reason we still have anything is because it got backed up to a flash drive in the IT guy's office and we were able to roll it back a couple days.

NGL deleting a folder of what is believed to be old files hardly sounds like an unreasonable thing to do. Out of context, at least.

Not having at least 2 backups of mission-critical stuff ready to go for exactly this kind of situation? Now THAT is a stupid move. I set up my own personal backup server just for my PC a long time ago, even though, realistically, the worst that would happen if I lost my data is that I would be extremely upset for a very long time.

3-2-1 rule for backups, fool. At least 3 copies, in at least 2 different formats, with at least 1 of them off-site.

>>

>>2968634

>It uses nearly full size cutters and can cut the same materials so not really

It can only make relatively light cuts no thanks to flimsy as fuck column tilt joint, among other things. You can do some nice things with it but it's nowhere near as capable as a big knee mill or even its bigger table top siblings.

On the other hand I also have a 3018 cnc model with spring-loaded nuts and fully 3d printed X and Z axes that's essentially a sponge compared even to the proxxon, it can't even cut plastic and really is only good for laser engraving, still I've managed to use it to mill molds out of wax with quite decent results.

Right tool for the job or so they say.

>>

>>

>>

>>2968098

the bigger mills are worth it, but just realize you're gonna spend like 2 or 3 grand hiring people and equipment to move or ship it when it probably wont even work on your home's electric system because that shit draws a fuck ton of power

a bridgeport is atleast portable for a diyer and shouldnt draw more than 15 amps of power

>>

>>

File: upgrade.jpg (360 KB)

360 KB JPG

I'm upgrading my mill, the quill on these sherline machines are unsupported and flap around like a motherfucker when you try to mill steel. What do you guys think about these two designs?

Left is quick and dirty, requires no welding and is probably stiffer front to back, but looks like shit. Right is going to require a lot of work including welding the pieces together and it won't take up as much load as the left, but it will have more points on contact to the base. The left will be bolted to the column base by two or four bolts from the inside surface of the steel tube. The right will be bolted with two bolts on each of the three faces of contact, and maybe I'll add a horizontal plate at the bottom of the tube that will mount to the top of the column base.

I think either case the weak point then becomes the thin saddle and plastic gibs and the column will be more than stiff enough.

>>

File: Resized_rif-1681070472118_489500513428841.jpg (290.2 KB)

290.2 KB JPG

>>2969355

>features you have no use for in a home workshop

do you put rigid tapping a toolchanger and flood coolant in that category?

>>

>>2969426

I mean stuff like pallet changer. Yeah it's a cool feature but it's a lot of complex machinery waiting to break down that will save you zero time or effort on occasional one-off jobs it will see in a home workshop.

Also flood cooling is more of a liability in that kind of machine. It's a big tank of liquid that you'll have to fill with something that isn't just tap water and then deal with it drying and clogging something, getting mold etc. without constant use and regular replacement a proper factory would have.

>google it

>930L / 245gal base tank on 630i

Yeah, good luck with that

>>

File: images(1).jpg (56.1 KB)

56.1 KB JPG

>>2969416

Avoid welding if you can because shit will warp, it's also harder to fix if something goes wrong. Several bolts spread apart as far as possible will work almost as good. Provide some ways for adjustment with the thing fully assembled because none of the parts you join together will be flat, straight or square unless you've personally made them so. Even the ones that appear to be surface ground from the factory. When mounting something to a tube like that keep in mind that even if it's rigid as a whole, it's still a thin sheet of metal locally and will flex easily so you need to spread the loads.

I'm not familiar with your specific machine but from the pics I'd have done something like on the right but with the column and the ways joined using bolts in a way similar to pic related in 3 or 4 points along the height with 2 bolts side to side at each point to transfer not just back to front force but the twist as well. It could then be easily adjusted in pretty much every direction as well. It won't be as good as a proper mill, but still light years ahead of the stock design.

>>

>>

>>

File: Capture.jpg (153.8 KB)

153.8 KB JPG

>>2969440

The column can't be attached to the ways anywhere except the top because the leadscrew is on the backside and transfers motion by a nut that reaches around the side.

Yeah sherline machines are fucking retarded, but they're the best tabletop machines you can get here. There's no other mill available that you can cut steel with and then pick up and put away when you're done because it only weighs 36lbs.

I'm working on making the left one.

>>

>>2969536

>the leadscrew is on the backside and transfers motion by a nut that reaches around the side.

Oh right, should've seen that coming. Still unless there are more surprises not shown on you pic you can still put a few bolts on one side.

Left version will work but I can see the column wall flexing easily at where it's attached to the base even with 4 bolts. Not much room for adjustment as pictured either.

>>

File: 006.jpg (305.6 KB)

305.6 KB JPG

>>2969564

I think it really won't make a difference because the contact point at the top can only be a max of 1.25"w x 1"h. And my ability to drill holes accurately is pretty limited so I'll be doing only two 10-32 screws into the cast iron ways.

Pic related, only one other person seems to have done this before.

I'll put reinforcing plates made of aluminum inside instead of washers, that should help. I think if I tried to make the design on the right it would end up being floppy at the point where it transitions from the plates to the tube.

>>

>>2969564

Just do it how cnc machines do, bearing cap, bolts on either end of your ballscrew/lead screw limit your travel by switches to prevent carrier from crashing into these caps

Why are you trying to do some crazy DMG Mori EVO magnet way bullshit on a $250 desktop milling machine

>>

>>

File: Screenshot 2024-06-22 092737.png (122.4 KB)

122.4 KB PNG

I'm sick of programming websites, I want to produce something more real. Do CNC programmers make good money? It seems like CNC programming would be more specialized than websites because few people have access to a CNC machine that they can practice on.

>>

>>2969879

A "CNC programmer" is in fact a CAD/CAM software operator. As one you need of course to know g-code for debugging and troubleshooting and having a general idea on what's going on, but if you're routinely writing it by hand it's either something too primitive to even need the cnc in the first place, or you're just wasting your time on doing what a computer would do faster and better.

>few people have access to a CNC machine that they can practice on

Anyone with a 3d printer or a router or any of the million cheap chink CNCs on the market. They all operate on the same code and basic principles as the big industrial machines and only lack support for some complex commands as well as higher end gimmicks like tool changers, probes, various coolant options, spindles etc., which are often brand or machine specific so you'll have to learn it at your workplace anyways. If anything it might be better to start with a cheap machine that you will have to babysit through stuff that big machines will automate away or just plow through, leaving you clueless when they fail to, and that you can crash all day long without bankrupting yourself.

>>

>>

>>

>>

>>

>>

File: 1722448243452046.jpg (122.7 KB)

122.7 KB JPG

computers for homebrew cncs make me feel old and cranky. i just need a shitty pc to run win7 so i can make my burn table go again and thats getting hard to do since gay ass w10 came about. cant find a mini pc thatll boot 7 even fucking around with uefi patch shit

the computer is supposed to be the easy part